Started focusing on micro machining; began exhibiting at the Micromachine Exhibition 2001

We started micro processing by cutting, EDM, and grinding. We introduced laser processing machine for fine hole drilling in 2017. It make us approach more wide range micro machining.

We introduced fine laser for surface machining in 2023. Our precision machining area is spread to the area where mechanical tools can not approach.

Micro-Hole Processing

There are various applications for small-diameter holes, such as the following examples:

- Single Holes – Several Hundred

- Nozzle: Suction, Coating

- Orifice

- Multiple Holes (Over Several Thousand Holes)

- Suction Plates, Chuck Plates

- Press Molds

- Fine Slit Holes

- Optical Components

- Equipment part

2700-φ0.10 4350-φ0.05

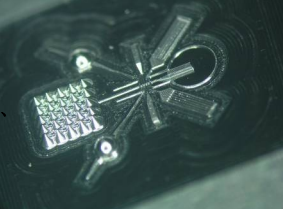

Micro-Shape Processing

- Possible methods include end mill processing, sinker EDM, grinding, and laser processing.

- Needle Shapes

- Used in Micro-needles, Anchors (Square Pyramids), and imprint molds and more.

- Fine Grooves

- Micro-channels, V-grooves for cable fixation,

- Suction grooves and more.

Cone Processing and Fine Grooves

Groove Width 0.07 Depth 0.04

Materials

- Steel

- Stainless, Aluminum, Copper

- Tungsten carbide, Ceramic, Machinable Ceramic

- Molybdenum, Tungsten, Inver etc

- Glass

- Carbon